RFID as the Digital ID Infrastructure of Robotic Systems

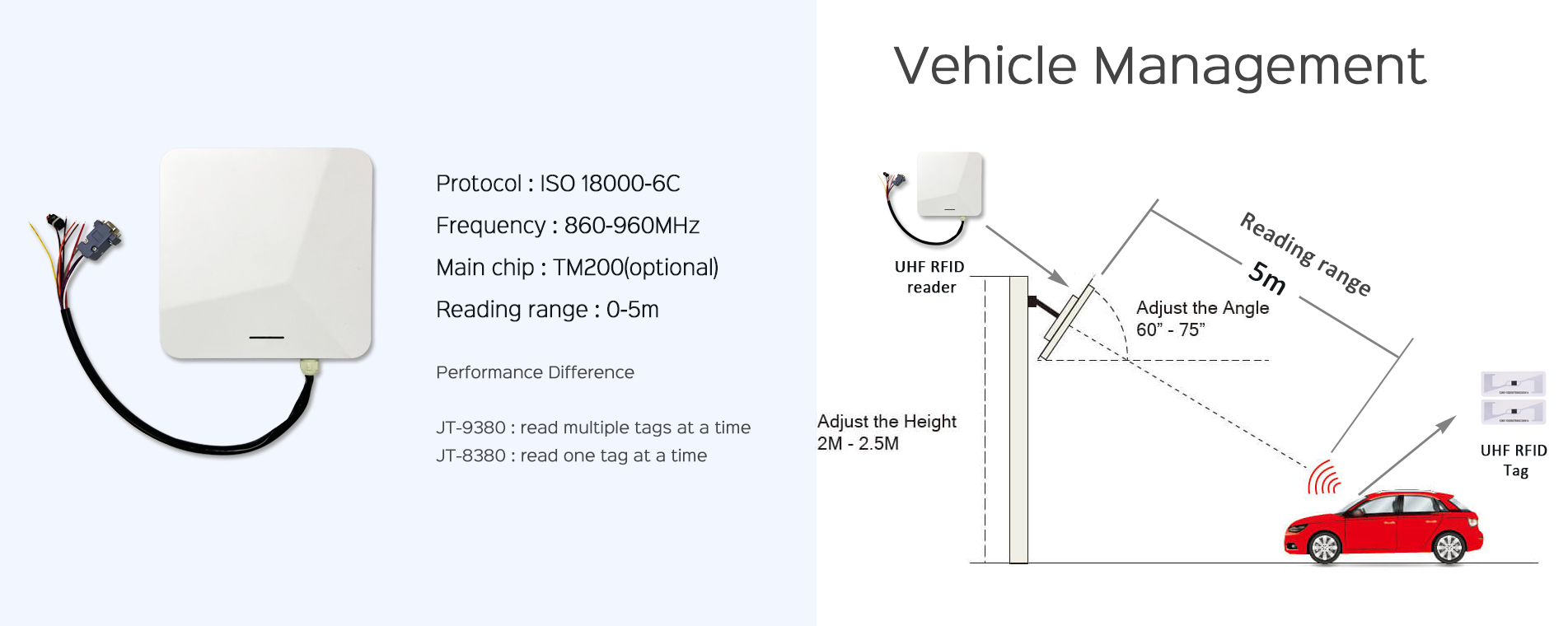

If one of the most profound transformations of the past two decades has been the digitalization of human identity—through ID cards, phone numbers, online accounts, and digital wallets—then the next two decades will witness a quieter but equally significant shift: machines are being systematically assigned identities of their own. As robots move beyond isolated tools and enter factories, warehouses, hospitals, city streets, and even homes—collaborating with humans and other machines—a fundamental question can no longer be avoided: how does a system know who a machine is? In human society, this question is answered by identity cards, passports, and social identification systems. In the emerging robotic society, that role is increasingly being played by RFID. A robot without a stable, verifiable identity can only be treated as a replaceable device. Once it is given a recognizable and traceable identity, however, it becomes part of a managed system—subject to rules, permissions, and responsibility. Identity is the line that separates tools from participants. In the early days of automation, robots did not need identities. A robotic arm performed fixed movements, an AGV followed predefined routes, and recognizing the individual machine was largely irrelevant. Today, this assumption no longer holds. Robot populations are growing rapidly, collaboration is becoming more complex, and robots are being deployed in open and semi-open environments. Systems must know which robot is executing a task, whether it is authorized to enter a restricted area, and who—or what—is responsible when something goes wrong. Under these conditions, identity has shifted from a “nice-to-have” feature to a foundational requirement. Some may ask why IP addresses or QR codes are not sufficient. These solutions can work within limited, closed systems, but they are poorly suited to serve as the foundational identity mechanism of a machine society. IP addresses depend on network connectivity and are inherently changeable. QR codes require line-of-sight scanning and human or camera intervention, which reduces reliability in industrial and harsh environments. RFID, by contrast, offers contactless identification, strong uniqueness, physical embeddability, and environmental robustness. In practical deployments, identity recognition is typically enabled by a combination of RFID chips and uhf rfid antenna systems, allowing machines to be identified reliably without physical contact or human participation. Within a robotic society, RFID is not merely a serial number—it is the physical root of a digital identity system. Each RFID chip carries a unique identifier that can be bound to a robot at manufacturing or during system onboarding. Even when a robot is offline, powered down, or partially disassembled, its identity remains intact. Around this physical anchor, backend systems build comprehensive mappings that link the RFID ID to model information, ownership, permission levels, operational s...

January 29, 2026

portuguêspt

portuguêspt chamada na :

+86 18681515767

chamada na :

+86 18681515767

o email :

marketing@jtspeedwork.com

o email :

marketing@jtspeedwork.com